29

2025

-

05

2024 Annual Quality and Integrity Report

2024 Quality and Integrity Report

Company Name: Zhejiang Shangyou Cutting Tools Co., Ltd.

Compilation Date: February 2025

Compiler: Wang Qiang

1

Contents Table of Contents

Preface....................................................1

I. Company Profile.............................................3

II. Quality Philosophy.............................................3

III. Enterprise Quality Management.........................................6

(I) Quality Management Organization.......................................6

(II) Quality Management System......................................12

(III) Quality and Safety Risk Management..................................14

(IV) Quality and Integrity Operation Management..................................16

(V) Marketing Management..........................................20

IV. Quality Management Foundation........................................21

(I) Standard Management..........................................21

(II) Metrology Management..........................................21

(III) Certification Management..........................................22

(IV) Inspection and Testing Management......................................22

V. Product Quality Responsibility........................................23

(I) Product Quality Level......................................23

(II) Product After-Sales Responsibility......................................24

(III) Corporate Social Responsibility......................................25

(IV) Quality Credit Record......................................31

VI. Report Conclusion............................................32

2

Preface Foreword

This report is the first publicly released "Enterprise Quality and Integrity Report" of Zhejiang Shangyou Cutting Tools Co., Ltd. (hereinafter referred to as "Shangyou," "our company," or "the company"). It is compiled in accordance with the provisions of the national standards of the People's Republic of China GB/T 29467-2012 "Implementation Specification for Enterprise Quality and Integrity Management" and GB/T 31870-2015 "Guideline for Writing Enterprise Quality Credit Report," and the company's 2024 quality and integrity system construction situation.

Our company guarantees that the information contained in this report does not contain any false records or misleading statements, and assumes responsibility for the authenticity and accuracy of its content.

Report Scope:

The organizational scope of this report is Zhejiang Shangyou Cutting Tools Co., Ltd. This report describes the company's concepts, systems, measures, and performance in quality management, product quality responsibility, and quality and integrity management from January 2024 to December 2024.

Report Publication Format:

Our company publishes a quality credit report annually. This report is published to the public in the form of a PDF electronic document on the company's website (http://www.shangyoutools.com). We welcome you to download, read, and provide valuable feedback.

3

General Office Statement

To ensure responsibility to customers and the scientific, fair, and effective inspection and testing, and to provide an independent and objective evaluation of testing quality with true and reliable testing data, the company's responsible person makes the following statement:

(1) Strictly abide by national laws, regulations, and policies on quality, adhere to a scientific and fair stance, strictly implement standards, and bear legal responsibility for the data provided.

(2) The company has established a quality system in accordance with GB/T 19001-2016/ISO 9001:2015 quality management system. In various quality activities, it strictly follows the procedures and methods stipulated in the "Quality Manual," implements full-process and full-element control over the quality of testing work, and can ensure the accuracy and reliability of the testing results.

(3) Independently conduct testing work, possess high-quality testing personnel and other hardware resources, and can provide "scientific, fair, accurate, and efficient" testing technology. In the testing work, it is not subject to any interference from administrative, commercial activities, or financial matters. It is not controlled by economic interests and ensures the independence and integrity of testing at all times.

(4) Strictly abide by the principle of confidentiality and relevant regulations, and be responsible for the authenticity of the test data.

(5) Strictly be responsible to customers, strictly implement various internal standards, and ensure product quality.

Chief Quality Officer Certificate and Oath

4

I. Company Profile

Zhejiang Shangyou Cutting Tools Co., Ltd. is currently the only professional manufacturer of high-precision and complex gear cutting tools in Zhejiang Province. It is located at No. 9, 25th Street, Eastern Industrial Park, Wenling City. Established in August 2004, the company mainly focuses on the research, development, production, and sales of high-speed gear hobbing cutters, gear shaping cutters, and gear shaving cutters. Its technology and product quality are at the leading level in the industry, with a high market share, representing the development level of China's gear hobbing, shaping, and shaving cutters.

The company was among the first in its industry to establish an ISO 9001 quality management system and has passed ISO 14001:2015 environmental management system certification. The company's standardized management and orderly operation adhere to sustainable development. Its sound R&D institution, excellent innovation capabilities, and strong brand awareness have earned the company numerous honors, including "Zhejiang High-tech Enterprise," "Zhejiang Specialized, Refined, and Innovative Small and Medium-sized Enterprise," and "Zhejiang High-tech Enterprise Research and Development Center." The company attaches importance to product quality innovation, increases investment in scientific research and hardware, and occupies the market with high-tech products. It has currently obtained more than 30 domestic patents and is a provincial patent demonstration enterprise.

The company possesses various types of sophisticated professional production equipment: imported advanced equipment such as the 6-axis fully CNC hobbing and grinding machine from Germany's SMS company, high-precision 3-axis CNC grinding wheel dressing machine; Sunnen internal honing machine from the United States; Taiwan CNC 5-axis linkage sharpening machine; nationally leading shaft and end face grinding machine; high-precision gear shaping cutter grinding machine from Germany's NILES; CNC gear shaping cutter grinding machine; Germany's Klingenberg P26, P65 gear testing equipment. Product processing and testing are carried out in a constant temperature environment to ensure the reliability and stability of product quality. The company can provide high-precision, high-tech, and high-performance non-standard complex cutting tools for the automotive, wind power, mining, heavy machinery, machine tool, shipbuilding, and railway vehicle industries.

5

II. Quality Philosophy

From its inception, the company has been committed to creating high-quality products, regarding product quality as the cornerstone of the company's survival and development. The company has successively passed the certifications of IS09001, IS014001, and OHSAS18001 management systems, various TLC product certifications, as well as safety production standardization and service certifications. It strictly adheres to this international quality management system, ensuring the quality of its products and facilitating the smooth implementation of the company's quality policy. To fundamentally strengthen quality management and improve the company's operational quality, the company uses the introduction of the excellent performance model as an opportunity to promote Total Quality Management, utilizing various quality statistical tools. Through internal audits, self-assessment, third-party audits or assessments, and QCC quality control circle activities, the company continuously seeks improvement opportunities and methods for continuous improvement, striving for excellent performance. Since its establishment, the company has never experienced any major quality complaints, and in annual inspections by various levels of quality supervision departments, the pass rate has always been 100%.

Table 1: Company Culture and Quality Culture

| Corporate Mission |

Realize corporate dreams, reflect employee value, benefit the public, and revitalize national industries. |

| Corporate Vision |

Build a century-old enterprise, keep pace with the times, and strive for excellence. |

| Core Values |

Be a person with a grateful heart, and do things with a sincere heart. |

| Quality Policy |

Integrity and law-abiding, excellent service, delivering quality products to customers. Pollution reduction and noise reduction, energy saving and consumption reduction, green contribution to society. |

| The integrated management policy is consistent with the company's business management policy, reflecting the company's quality, environmental, occupational health and safety management objectives and direction, including: compliance with national laws and regulations, meeting the quality, environmental, and occupational health and safety requirements stipulated in the contract; earnestly serving customers and society, enhancing their satisfaction, and establishing a good image for the company in the market; pursuing improvements in the management system and enhancing the level of system management; the company's top management should regularly review the integrated management policy and make necessary revisions. |

Table 2: Company Quality Objectives

| Process |

Quality Objective |

Target Value |

Calculation Method |

Statistical Period |

|

| COP1 |

Order Receiving and Review |

Order Review Timeliness Rate |

100% |

Order Review Timeliness |

Month + Year |

| COP2 |

Project Management |

On-time Completion of Product Design and Development Rate |

95% |

Number of tasks completed on schedule / Total number of tasks * 100% 务数*100% |

Annual |

| COP3 |

Product Manufacturing |

Production Plan Completion Rate |

90% |

Number of qualified products actually produced / Planned production number * 100% 产数*100% |

Month + Year |

| Defect Rate |

8.0% |

Defective products / Total number of products * 100% |

Month + Year |

||

| Scrap Rate |

3.0% |

Scrap quantity / Total quantity * 100% |

Month + Year |

||

| Shipment Plan Achievement Rate |

90% |

Actual shipment quantity / Planned shipment quantity *100% |

Month + Year |

||

| COP4 |

Product Delivery |

On-time Delivery Rate |

100% |

Number of on-time deliveries / Total number of deliveries * 100% |

Month + Year |

| COP5 |

Customer Feedback |

Number of Customer Complaints |

2 times/ Month |

Monthly Total |

Month + Year |

| SP1 |

Employee Satisfaction |

85% |

Employee Satisfaction Survey Scoring Method |

Half Year |

|

6

| Process |

Quality Objective |

Target Value |

Calculation Method |

Statistical Period |

|

| Human Resource Management 理 |

Employee Turnover Rate |

5.0% |

Number of employees who resigned this month / (Number of employees at the beginning of the month + Number of employees at the end of the month) / 2 初员工人数+当月月末员工 人数)/2 |

Month + Year |

|

| SP2 |

Infrastructure |

Annual Inspection Completion Rate of Special Equipment |

100% |

Actual number of verifications / Planned number of verifications * 100% |

Year |

| SP3 |

Process Operation Environment |

Number of Recurring Occurrences of Similar Issues in Process Environmental Inspections 重复发生次数 |

≤1 time |

/ |

Month + Year |

| SP4 |

Measurement Equipment Management 理 |

Calibration and Verification Plan Completion Rate |

100% |

Actual number of calibrated and verified items / Planned number of items * 100% |

Annual |

| SP5 |

Laboratory Management |

Test Completion Rate |

100% |

Actual number completed / Planned number * 100% |

Month + Year |

| SP6 |

Knowledge Management |

Knowledge Submission Plan Completion Rate |

90.0% |

Actual number of knowledge submissions / Planned number |

Half Year |

| SP7 |

Capability and Awareness |

Training Plan Completion Rate |

100% |

Actual number of training sessions / Planned number of training sessions * 100% |

Month + Year |

| SP8 |

Documented Information |

Document Distribution and Recovery Rate |

100% |

Number of documents recovered / Number of documents distributed x 100% |

Month + Year |

| SP9 |

Supplier Management |

Supplier Performance Evaluation Score A Grade Ratio |

80% |

Number of Grade A suppliers / Total Number of Suppliers |

Month + Year |

| SP10 |

Procurement Management |

Supplier Delivery Punctuality Rate |

100% |

Number of on-time deliveries / Total number of deliveries * 100% |

Month + Year |

| Supplier Batch Qualification Rate |

97% |

Number of qualified batches / Total number of procurement batches *100% |

Month + Year |

||

| Supplier Arrival Rate |

95% |

Actual arrival quantity / Planned arrival quantity Quantity |

Month + Year |

||

| SP11 |

Equipment Management |

Equipment Maintenance Plan Completion Rate |

100% |

Actual maintenance quantity / Planned maintenance quantity * 100% |

Month + Year |

| OEE (Overall Equipment Effectiveness) |

80% |

Availability x Performance x Yield Rate |

|||

| SP12 |

Tooling and Die Management 理 |

Die Failure Rate |

5% |

Actual number of die failures / Total number of dies *100% |

Month + Year |

| SP13 |

Gauge Management |

Gauge Calibration Plan Completion Rate |

95% |

Actual number of calibrations / Planned number of calibrations * 100% |

Year |

| SP14 |

Identification and Traceability Traceability |

Product Identification Spot Check Compliance Rate |

95% |

Number of correct spot checks / Total number of spot check inspection procedures x 100% |

Quarter |

| SP15 |

External Property |

External Property Loss Rate |

5% |

Number of losses / Total number of customer properties |

Quarter |

| SP16 |

Protection Management |

Inventory Turnover Rate |

15% |

Sales / Inventory product and material value x 100% |

Month + Year |

| Warehouse Accounting Accuracy Rate |

100% |

/ |

Quarter |

||

| SP17 |

Change Management |

Number of Change Risk Occurrences |

1 time / Month |

Actual number of risks occurred |

Month + Year |

| SP18 |

Products and Services Release |

Finished Product Spot Check Qualification Rate |

98% |

Number of qualified spot checks / Total number of spot checked products *100% |

Month + Year |

| Number of Factory Inspection Misses |

≤2 times |

Number of Factory Inspection Misses |

Month + Year |

||

7

| Process |

Quality Objective |

Target Value |

Calculation Method |

Statistical Period |

|

| SP19 |

Nonconformance Control |

Comprehensive Finished Product Rate |

97% |

Number of finished products / Number of input materials x 100% |

Month + Year |

| SP20 |

Customer Satisfaction Measurement |

Total Customer Satisfaction Score |

90% |

Survey form, comprehensive evaluation of delivery performance Method |

Annual |

| SP21 |

Nonconformity Correction Measures |

Number of Recurring Problems |

≤2 times |

Number of Recurring Problems |

Quarter |

| MP1 |

Organizational Environment and Stakeholder Needs |

Number of stakeholder customer risk occurrences Number |

≤3 times |

Actual number of stakeholder customer risk occurrences Number |

Annual |

| MP2 |

Risk and Prevention Management |

Number of Major Risks Occurred |

≤1 time |

Number of Major Risks Occurred |

Annual |

| MP3 |

Performance Analysis and Evaluation |

Number of times the substandard target has been repeated Number of times |

≤1 time |

Number of times the substandard target has been repeated |

Month + Year |

| MP4 |

Internal Audit |

Internal Audit Plan Completion Timeliness Rate |

100% |

Audit completion time / Planned completion time x 100% |

Year |

| MP5 |

Management Review |

Management Review Punctuality Rate |

100% |

Actual / Planned |

Annual |

| MP6 |

Quality Cost |

Defective Quality Cost Rate |

1.9% |

(Internal losses + external losses) / Sales Sales |

Month + Year |

| MP7 |

Continuous Improvement |

Continuous Improvement Target Achievement Rate |

95% |

Number of improvement projects implemented / Number of planned improvement projects per year x 100% |

Quarter |

8

III. Enterprise Quality Management

(I) Quality Management Organization

With a high degree of emphasis on product quality, the company has established a quality manager system and formulated inspection standards for various materials, components, and products. Each department performs its duties, communicates and coordinates with each other, and strengthens product quality control throughout the R&D, procurement, and production processes.

Integrated management policy for quality/environment/occupational health and safety:

a. The company establishes an integrated management policy for quality, environment, and occupational health and safety, ensuring that the policy aligns with the organization's objectives;

b. This includes a commitment to meeting customer and regulatory requirements and continuously improving the effectiveness of the quality management system;

c. Provides a framework for setting and reviewing integrated management objectives for quality, environment, and occupational health and safety;

d. Top management must communicate, disseminate, and ensure understanding and implementation of the integrated management policy for quality, environment, and occupational health and safety within the organization through training and communication, to achieve the ultimate goal of the policy;

e. The company reviews and revises the suitability of the integrated management policy for quality, environment, and occupational health and safety through management review to adapt to changes in the internal and external environment;

f. The integrated management policy for quality, environment, and occupational health and safety must be documented, approved by the general manager, and implemented;

Roles, Responsibilities, and Authorities of the Organization

Top management determines the company's organizational structure, clarifies responsibilities and authorities, and implements internal communication.

Responsibilities and Authorities

1) The company defines the responsibilities and authorities of each functional department and their interrelationships, and communicates, guides, and controls the coordination of activities related to quality, environment, and occupational health and safety within the company organization to promote effective integrated management of quality, environment, and occupational health and safety;

2) The company's integrated management system (IMS) structure, responsibilities, authorities, and interrelationships are shown in the organizational chart.

3) The responsibilities and authorities of personnel in various departments and their interrelationships are shown in the "Departmental Position (Responsibilities) Description" and "Individual Job Responsibilities"; the company achieves communication through the release of the "Management Manual" and "Individual Job Responsibilities" documents, enabling all employees to clearly understand their responsibilities, participate fully, and effectively carry out various activities.

General Manager

1) Based on national policies, laws and regulations, and market development trends, comprehensively plan the company's and product's development direction;

2) Establish the company's integrated management policy and objectives for quality, environment, and occupational health and safety, aiming to enhance customer satisfaction, ensuring attention to customer requirements, and clarifying the direction for company development;

3) Plan, establish, and implement an integrated management system for quality, environment, and occupational health and safety using the "process approach," and continuously improve its effectiveness to meet the requirements of the objectives;

9

4) Determine the company's organizational structure, clarify the responsibilities and authorities of each department, and ensure internal communication;

5) Ensure the provision of necessary resources for the establishment, implementation, and improvement of the integrated management system, creating a work environment that enables all employees to fully participate in achieving the integrated management objectives for quality, environment, and occupational health and safety, giving full play to employee initiative and talent to bring maximum benefits to the company;

6) Appoint a management representative, determine their responsibilities and authorities, and provide support to ensure the establishment, implementation, and maintenance of the integrated management system process;

7) Pay attention to customer satisfaction, examine the performance of the quality management system, preside over management reviews, review the suitability, adequacy, and effectiveness of the quality management system, and continuously improve it to achieve the company's established goals;

8) Take full responsibility for the quality of the company's products.

Management Representative

1) In accordance with the requirements of the company's integrated management policy and objectives for quality, environment, and occupational health and safety, cooperate with the general manager to plan the integrated management system, ensuring that the processes of the integrated management system are established, implemented, and maintained;

2) Report to the general manager on the achievements made in the integrated management system for quality, environment, and occupational health and safety, and propose the needs for improvement of the integrated management system for quality, environment, and occupational health and safety, contributing to the improvement of system processes;

3) Enable all employees throughout the company to recognize that the company depends on customers, and that meeting customer requirements is crucial to the company's fate—a quality awareness.

4) Responsible for the liaison and communication with external parties, including customers, regarding the company's integrated management system for quality, environment, and occupational health and safety;

5) Responsible for organizing the preparation of the management manual and procedural documents; develop a management review plan, organize management reviews, supervise the implementation of review resolutions, and conduct follow-up verification and reporting; responsible for reviewing the "Management Manual" and approving procedural documents.

Shared Responsibilities of Department Heads

1) Implement the company's integrated management policy for quality, environment, and occupational health and safety, achieve the department's integrated management objectives for quality, environment, and occupational health and safety, and contribute to the achievement of the company's integrated management objectives for quality, environment, and occupational health and safety;

2) Implement the resolutions/instructions of the general manager, supervisor, and management review meeting regarding quality, environment, and occupational health and safety work, and preside over various integrated management work for quality, environment, and occupational health and safety in the department;

3) Determine the establishment of departmental positions and responsibilities, implement and improve the departmental responsibility system to ensure that the department's work proceeds in an orderly manner;

4) Develop "_Departmental Position (Job) Description" and "_Departmental Individual Job Responsibilities," determine the on-the-job ability requirements for various positions in the department, conduct assessments and evaluations of personnel in various positions, and provide training to ensure that personnel in various positions have continuous competence;

5) Collect and analyze information/data related to the department, evaluate improvement needs, and implement continuous improvement;

6) Participate in relevant integrated management analysis meetings for quality, environment, and occupational health and safety.

7) Participate in management reviews, report on the performance and improvement suggestions of the department's integrated management system for quality, environment, and occupational health and safety, and contribute ideas for system improvement;

Technical Department Manager

1) Responsible for product realization planning, preparation of quality plans for special products, projects, and contracts, and responsible for the quality of special products, projects, and contracts;

2) Responsible for the centralized management of design and development, and responsible for the quality of design and development (compliance with hygiene and safety regulations, meeting customer needs and standards);

3) Responsible for the control and centralized management of design and development output drawings and documents, and responsible for the adequacy, suitability, and effectiveness of the distribution of drawings and documents;

4) Responsible for the application research and adoption of new materials and technologies, improving the company's technical level and product quality;

5) Manage drawings and/or samples provided by customers and protect customer property;

6) Cooperate with the production department to solve major technical quality problems;

7) Responsible for the control of management system documents and records required by the integrated management system for quality, environment, and occupational health and safety;

8) Responsible for the implementation and control management of product status identification;

9) Responsible for the control and management of monitoring and measuring equipment;

10) Cooperate with senior management in the planning of company-required measurement analysis and improvement processes;

11) Monitor and measure processes, propose improvement measures to enhance process capabilities, and implement tracking of their effectiveness;

12) Responsible for the formulation of inspection standards for the entire process of product incoming inspection, product realization (including trial production and mass production), and finished products, and for the monitoring and measurement of products, ensuring the conformity of transferred, released, and factory products;

13) Responsible for the identification and review of nonconforming products, supervise and track the handling of nonconforming products, and responsible for the reinspection of reworked products and the statistics of quality indicators;

14) Responsible for determining, collecting, and analyzing data from monitoring and measurement, evaluating improvement needs, organizing corrective/preventive/improvement measures, tracking and verifying effectiveness, and being responsible for the effectiveness of continuous improvement;

Production Department Manager

1) Oversee the management of materials and finished products in the material warehouse and finished product warehouse;

2) Responsible for reviewing product delivery dates in sales contracts, formulating production plans and material procurement plans, ensuring smooth production and logistics, and being responsible for the timely completion of production plans and on-time delivery;

3) Responsible for the safety of stored materials in material/finished product warehouses, and for the proper labeling and protection of stored materials;

4) Responsible for formulating relevant internal warehouse management regulations;

5) Regularly inventory stored materials to ensure consistency of warehouse items' accounts, physical inventory, and cards;

6) Load and ship products according to customer requirements, and be responsible for contacting customers and monitoring and measuring customer satisfaction.

7) Responsible for the centralized management of the company's raw materials, components procurement, and outsourcing processes, conducting supplier assessments and reassessments, and being responsible for the quality and timeliness of incoming raw materials, components, and outsourced parts;

8) Implement the "mutually beneficial relationship with suppliers" quality/environmental/occupational health and safety integrated management principles, actively collect market information on procurement and outsourcing materials, investigate and research new suppliers, develop suppliers with the best price-performance ratio, and strive to reduce product quality costs;

Administrative Department Manager

1) Responsible for the centralized management of the company's human resources, and responsible for the adequacy, suitability, and job competency of the human resources provided;

2) Cooperate with top management in planning the organizational structure and responsibilities, prepare the company's organizational chart and "Company Position (Job) Description," and organize various departments to prepare "Department Responsibilities, Individual Job Responsibilities" as the basis for on-the-job personnel assessment and recruitment;

10

3) Based on the needs of departmental personnel, propose departmental personnel allocation plans (including personnel appointments and removals), the construction of cadres and technical talent teams, and achieve optimal personnel allocation;

4) Based on the company's situation, organize the formulation of company recruitment management regulations, employee handbooks, annual training plans, training regulations, departmental functions, and job descriptions, and organize their implementation.

5) Responsible for the planning and implementation of company-wide training, responsible for training effectiveness, and responsible for recruitment effectiveness;

6) Develop recruitment plans and procedures, develop and introduce external talent, organize and implement recruitment work, and participate in the interview and screening of applicants;

7) Establish an internal communication mechanism within the company, understand employee dynamics in a timely manner, control personnel turnover rates; coordinate/resolve labor relations disputes.

8) Based on the company's development strategy, formulate scientific and feasible departmental work plans and implement them.

9) Draft investment documents, project approval, construction, and reporting for engineering projects;

10) Coordinate the company's vehicles, security, logistics, and canteen management, organize the formulation of scientific and reasonable management regulations, and implement them;

11) Coordinate the company's safety and fire protection work, employee social security, and work injury handling;

12) Responsible for the configuration, maintenance, and management of factory buildings, warehouses, and related facilities;

13) Responsible for the configuration, maintenance, and management of communication and information systems;

14) Responsible for the company's "three-in-one" management system audit work;

15) Responsible for the management of other company office affairs.

Workshop Directors

1) Responsible for the centralized management of personnel, machines, materials, methods, environment, and production operations in the workshop, achieving the integrated management goals of quality/environment/occupational health and safety in the workshop;

2) Execute production instructions from the production manager, organize the production of the workshop, strive to complete the production plan, and ensure product quality and delivery schedule;

3) Coordinate the product flow between various processes in the workshop, strive to achieve balanced production in each process, and perform production scheduling within the workshop;

4) Supervise operators in carrying out daily maintenance and maintenance of equipment and tooling;

5) Responsible for the control and management of the workshop's working environment, ensuring civilized and safe production;

6) Guide operators to operate strictly according to standards/drawings/processes/operating instructions, and make corresponding records to ensure product quality conformity;

7) Responsible for the labeling and traceability of processed products in the workshop, protecting inspection status labels, and protecting the property of customers in the workshop;

11

8) Handle product handling, packaging, and labeling protection according to regulations;

9) Guide employees in the correct use of monitoring and measuring equipment to ensure its accuracy and effectiveness;

10) Supervise operators in performing process self-inspection and cooperate with inspectors in performing inspections;

11) Handle the isolation, rework, repair, and scrapping of nonconforming products;

12) Responsible for the collection, statistical analysis, evaluation of improvement needs, and implementation of improvements for relevant data in the workshop;

Internal Auditor

1) Strictly in accordance with relevant laws, regulations, standards, and quality documents, conduct quality/environmental/occupational health and safety integrated management system audits according to company arrangements and in combination with the company's actual situation;

2) Collect and analyze relevant documents and materials, prepare audit checklists, prepare for the audit, and conduct on-site audits; eliminate interference during the audit, go all out, and be faithful to the audit objectives;

3) Manage relationships both inside and outside the audit group to achieve optimal audit results;

4) Respect objective facts, ensure the impartiality of the audit work, truthfully record the status quo of the audited department during the audit process, and write non-conformance reports;

5) Based on objective evidence, write objective, fair, and factual audit reports, propose the need for corrective measures, and verify their implementation effectiveness;

Inspector

1) Implement the company's integrated management policy for quality/environment/occupational health and safety, and diligently complete various inspection responsibilities stipulated in the management manual and procedural documents;

2) Strictly follow the requirements of relevant acceptance standards, inspection specifications, and drawings, independently exercise inspection powers, identify and record product quality, and ensure quality control;

3) Properly label the inspection status of products and record non-conforming items;

4) Carefully fill out quality records, organize, analyze, and feedback quality information;

5) Responsible for the rework, initial evaluation, and disposal of non-conforming products;

6) Receive training and continuously improve business capabilities;

Tester

1) Responsible for conducting functional testing of raw materials, outsourced parts, processed products, and finished products;

2) Responsible for comprehensive functional testing and evaluation of outsourced materials, new raw material samples, and new products;

13

3) Issue test reports and take responsibility for the accuracy of the data;

4) Responsible for the weekly inspection of testing instruments to ensure their accuracy;

5) Receive training on relevant national regulations and professional knowledge to improve personal quality.

(II) Quality Management System

Since the introduction of the quality management system, the company has adhered to the company's integrated management policy for quality/environment/occupational health and safety of "integrity and law-abiding, excellent service, fine products delivered to customers; pollution reduction, noise reduction, energy saving and consumption reduction, green contribution to society." Based on the requirements of the quality management system, a quality management system has been established around the design, development, production, and sales processes of gear hobs, forming a quality manual, procedural documents, and other quality documents, which are implemented, maintained, and continuously improved for effectiveness.

1. Quality Management System Policy and Objectives

The company's quality policy is: Integrity and law-abiding, excellent service, fine products delivered to customers

Pollution reduction and noise reduction, energy saving and consumption reduction, green contribution to society.

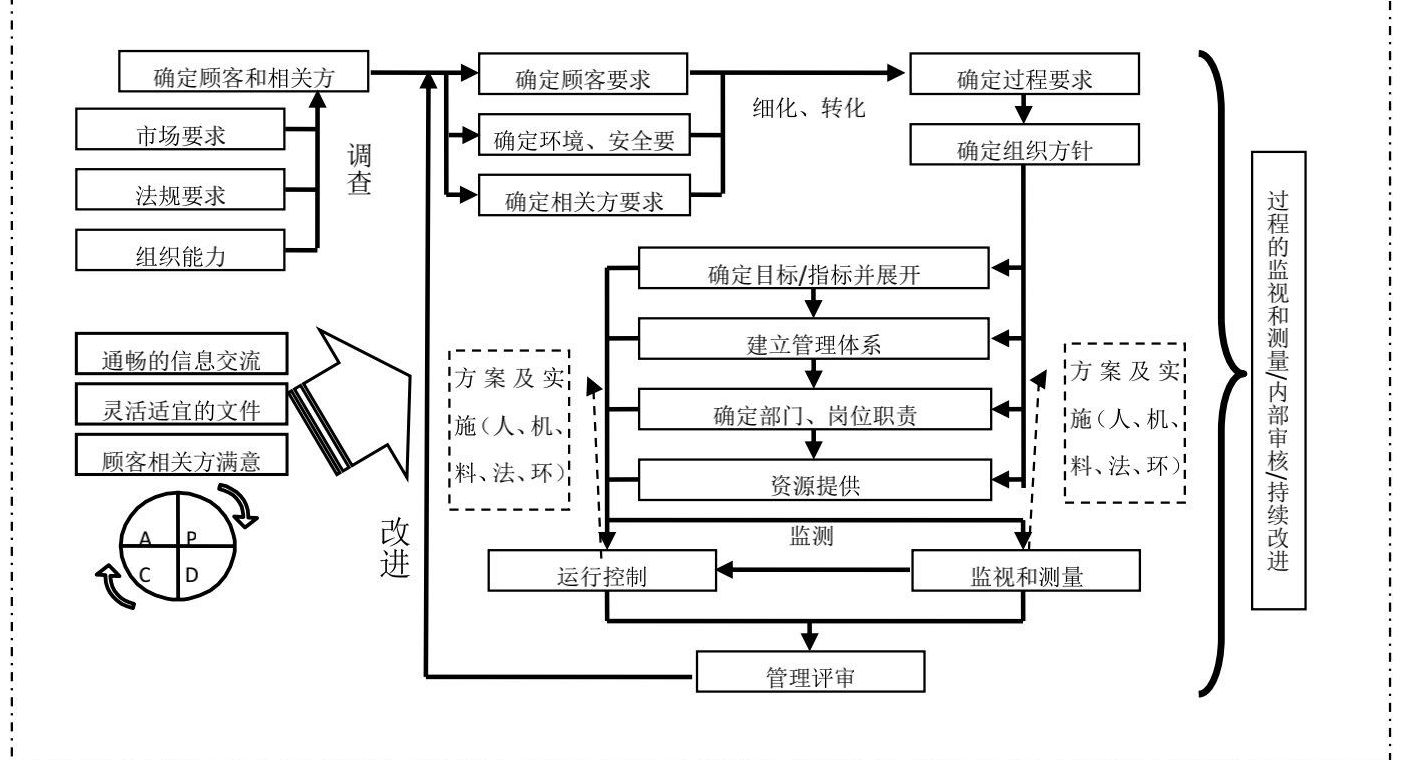

Figure 1 Diagram of the company's management system operation process

Company Quality Objectives:

① Customer inspection acceptance rate of 91% or higher;

② Product delivery timeliness rate of 95% or higher;

③ Customer satisfaction rate of 98% or higher.

12

Company Environmental and Occupational Health and Safety Objectives:

① Noise emission meets standards;

② 100% classified collection and treatment of production and living waste;

③ Zero incidence of occupational diseases;

14

④ Prevention of work-related injuries and fire accidents.

To achieve the company's quality and safety responsibility objectives, the company has established a sound quality and safety leadership organization, establishing a product quality and safety leadership committee headed by the general manager. Sub-committees are set up in various centers and functional departments to be responsible for the supervision and assessment of product quality and safety work.

The company has established an integrated comprehensive quality management system with strategy as its core and the GB/T19580 Excellent Performance Model as its framework, meeting the requirements of six major stakeholders: customers, shareholders, employees, suppliers, society, and partners. Corresponding strategic planning and quality objectives have been established at all levels of the company, and a quality assessment KPI and quality accountability system have been established based on the company's performance assessment system.

2. Quality Education

During the operation of the system, the company uses various scientific and effective methods for measurement, analysis, and improvement, based on the PDCA system method for continuous improvement. The company uses various tools to improve the performance of various departments and levels, and adopts benchmarking and learning methods to continuously correct individual work ideas and methods to ensure the achievement of individual and overall company goals. The company actively communicates and exchanges with external parties and invites experts to provide specialized training to company employees as needed. The company regularly conducts quality education for employees at all levels, and conducts specialized management of quality control points to ensure the consistency of product quality in the manufacturing process.

To firmly establish the integrity awareness of all employees, the company formulates an annual quality integrity education and training plan at the beginning of each year, implementing three-level quality integrity education and training. Department heads, according to company requirements, prepare education and training plans and content, and carefully organize the education and training of their subordinates. Workshop directors are responsible for the integrity publicity and education work of team leaders and employees. The company uses a variety of methods to implement quality integrity education for employees, including thematic training, posting or conveying written materials, exchange of experience of advanced employees in quality integrity, use of morning meetings or pre-shift meetings, and use of image displays. The company provides certain rewards to personnel who achieve excellent results in quality integrity education and training, and at the same time promotes and popularizes experience among employees. Employees who do not participate in quality integrity education and training on time or who fail the training assessment will be subject to certain penalties.

3. Quality Regulations and Responsibility System

The company collects laws, regulations, and other standards and requirements, and formulates relevant internal standards to ensure that products meet the requirements of national laws, regulations, and national and industry standards (some product indicators exceed external requirements), practicing social responsibility through product technology. At the same time, the company has formulated "Quality Reward and Punishment Management Standards", "Quality Assessment Management Measures", etc., to punish product quality problems, and follows the principle of not letting go of quality accidents.

Table 3 Quality standards and other relevant laws observed by the company

| Category |

Content |

| Company standardized governance |

"Company Law", "Enterprise State-owned Assets Management Measures", "Accounting Law", "Accounting Standards", "Financial Regulations" etc. |

| Protecting employee rights and Social responsibility |

"Safety Production License Regulations", "Special Equipment Safety Supervision Regulations", "Dangerous Chemical Safety Management Regulations", "Production Safety Accident Reporting and Investigation and Handling Regulations" etc. |

| Implementation of product standards and formulation/market access |

GBT 6083-2016 "Gear Hobs - Basic Types and Dimensions" GBT 6084-2016 "Gear Hobs - General Technical Conditions" ISO 4468-2009.MOD ISO 2490:2007 |

15

| Category |

Content |

| Internal and External Audit Mechanisms |

The company has established institutions such as a supervisory board and an internal audit department, and has signed a long-term audit cooperation agreement with Wenling Zhonghe United Certified Public Accountants Firm This has perfected an independent internal and external audit mechanism. |

The company has formulated "Internal Audit Management Procedures" and "Management Review Control Procedures," and has cultivated an internal audit team. To ensure the effectiveness and continuous improvement of the system's operation, system audits, process audits, product audits, and quality inspections are arranged. For nonconformities found during audits, the responsible department analyzes the causes, formulates corrective or preventive measures, implements rectification, and verifies the rectification effect. Finally, an internal audit report is generated, providing suggestions for system rectification and the prevention of nonconformities. This report serves as an important input for management review and is reported to the highest management level.

The company has formulated "Nonconforming Product Control Procedures," "Corrective and Preventive Action Management Procedures," and "Logistics Sampling Management Specifications" to strictly control nonconforming products. All company products undergo online inspection before being allowed to proceed to the next process or leave the factory. Any nonconforming products have clear requirements for identification, recording, isolation, and handling. All reworked or repaired nonconforming products must pass re-inspection before proceeding to the next process.

Meanwhile, according to the "Product Monitoring and Measurement Control Procedures," detailed records are kept for all nonconformities. A designated person performs statistical analysis, and the responsible unit formulates corrective and preventive measures based on the "Corrective and Preventive Action Management Procedures" and implements rectification. The problem item can only be closed after the effectiveness of the corrective and preventive measures has been evaluated.

In addition, the company has also formulated systems such as the "Quality Manual," "Supplier Control Procedures," and "Employee Training Management Measures." Accountability is enforced for quality issues, employees receive education, and systematic approaches are emphasized in daily R&D and production operations. Activities such as quality control circles and continuous improvement, along with the application of quality tools, fully utilize the PDCA cycle for continuous improvement and the pursuit of excellence.

(3) Quality and Safety Risk Management

To achieve the company's quality and safety responsibility goals, the company has established a sound quality and safety leadership organization. A product quality and safety leadership committee, chaired by the chairman of the board, has been established to oversee and evaluate product quality and safety work. In 2024, a "Chief Quality Officer (CQO)" system was established, clarifying the CQO's responsibilities and rights, and fully exercising the quality and safety "veto power." The Quality Department signs "Product Quality and Safety Responsibility Letters" with various departments, further implementing them at each position and conducting assessments.

Quality and safety knowledge is disseminated through the annual "Quality Month" activities in September to strengthen employees' awareness of quality and safety. Through the quality, environmental, and occupational health and safety management system audits, quality and safety hazards are promptly identified and eliminated.

During the design, production, and assembly processes, the following measures are mainly adopted to ensure quality and safety:

The design department conducts FEMA analysis and error-proofing design; the quality department strictly implements the "four inspections" system of initial inspection, patrol inspection, final inspection, and supervisory inspection;

| Project |

Content |

|

| Detection System |

Quality department personnel, production department personnel, and material preparation personnel are responsible for the detection and reporting of product quality issues during production work; purchasing department personnel are responsible for the detection and reporting of product quality incidents during finished product storage and loading and unloading. |

|

| Early Warning System |

The quality department, production department, and purchasing department, in accordance with their respective responsibilities, strengthen the detection and analysis of quality incidents, improve quality awareness and risk awareness, promptly analyze the feasibility of product use, and identify trends in problems, making timely warnings and ensuring the effective operation of the production system. |

|

| Emergency Response |

Major |

(1) The quality department organizes relevant departments to analyze the causes of the problem and, based on the impact of the incident, formulates corresponding emergency measures, including aspects such as product handling, impact elimination, and loss reduction; (2) Each department is responsible for promptly organizing relevant work according to the requirements of the emergency measures; (3) The quality department is responsible for inspecting the implementation of the emergency measures. |

| Significant |

(1) After a significant quality incident occurs, the quality department is responsible for promptly notifying relevant personnel to control the problematic products, and the purchasing department is responsible for isolating and identifying the same batch of problematic products or products that may have problems to prevent further circulation or shipment. (2) The quality department organizes relevant departments to analyze the causes, and the technology department provides corresponding technical support and gives processing opinions; (3) The production department is responsible for verifying the effectiveness of the measures. |

|

| General |

(1) The production department is responsible for promptly reporting the problem to the production department; (2) The production department analyzes the cause of the problem, formulates corresponding improvement measures, and implements them specifically; (3) The quality department/sales department verifies the rectification effect according to the corresponding situation. |

|

| Potential |

(1) Based on the principle of prevention first, potential quality incidents must be given high attention. Once a potential incident occurs, the quality department must be notified immediately, and the quality department will organize relevant personnel to assess the impact and hazard level of the potential quality problem; (2) Based on the results, formulate corresponding remedial measures and preventive measures to prevent quality accidents and reduce losses; (3) The quality department is responsible for verifying the effectiveness of preventive measures. If necessary, products need to be supplied from a designated point to facilitate timely and effective control of any spread. |

|

| Emergency Handling |

Product handling is the responsibility of the department where the problem occurred. After the problem occurs, the product should be quickly isolated and correctly identified. Before the final disposal of the product is issued, no one may dispose of the product arbitrarily; for products that need to be recalled, the quality department is responsible for recalling them, and after recall, they should be promptly isolated and identified. |

|

Table 4 Quality and Safety Emergency Plan

The company has formulated a quality and safety emergency plan and established an emergency leadership team with the general manager as the team leader, the quality authorized person and the executive deputy general manager as deputy team leaders, and the quality department, purchasing department, technology department, sales department, and finance department as members. The responsibilities of the emergency leadership team and each relevant department have been clearly defined.

The process department conducts process discipline checks on key processes every month;

16

Production manufacturing departments implement a manager responsibility system to track and supervise the entire production process;

Establish the concept of "quality is produced," where employees inspect their own products according to the drawings, determine whether they are qualified, and make relevant self-inspection records on the "Self-Inspection Form";

The modularized production model exposes and controls key quality aspects of the product, thus ensuring product quality and safety and preventing quality and safety risks.

17

IV. Quality Integrity Operation Management

(I) Quality Commitment

1. Requirements that the enterprise must comply with as clearly stipulated by laws, regulations, and standards related to the enterprise or product

During operation, the company shall operate and implement standardized governance in accordance with the Company Law, Accounting Law, Contract Law, Product Quality Law, Accounting Standards, Enterprise Income Tax Law, etc., and protect employee rights and social responsibilities in accordance with the Labor Law, Trade Union Law, Consumer Rights Protection Law, Environmental Protection Law, Safety Production Law, Occupational Disease Prevention and Control Law, ISO14001 standard, etc.

Products must be implemented according to:

GBT 6083-2016 "Gear Hobs - Basic Types and Dimensions"

GBT 6084-2016 "Gear Hobs - General Technical Conditions"

2. Integrity and Law Abidance

Senior leaders follow the management philosophy of "legal operation and integrity operation," strictly abide by the Company Law, Economic Law, Contract Law, Product Quality Law, Safety Production Law, Environmental Protection Law, Labor Law, and relevant laws and regulations of the machinery industry, strengthen employee legal knowledge training, cooperate with government departments to carry out legal education activities, encourage and commend employees' "positive energy," so that the style of integrity and law abidance is deeply rooted in the consciousness and behavior of all employees of the company. The company's contract default rate is zero, bank loans are never overdue, overdue receivables are reduced to a reasonable range, senior and middle-level leaders of the company have no records of violations of laws and disciplines, the number of employee violations is zero, and a good credit and moral image has been established among customers, users, the public, and society.

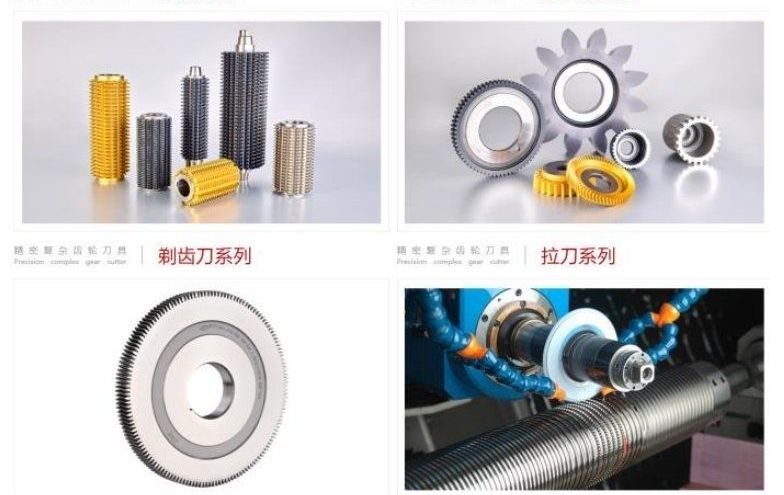

Figure 2 Various explicit commitments made by the enterprise in its public statements

Hob Series

Gear Shaper Cutter Series

18

2. Meeting Customer Needs

The company attaches great importance to technological research and development, strengthens investment in research and development, takes customer needs as the center, actively listens to customer opinions and suggestions on functions, quality, and configuration, carries out product improvement and innovation activities, and meets customer needs for products and delivery times. In terms of product quality, the company strictly implements the quality management system and ensures product quality and safety through technological breakthroughs, quality improvement, and QC group activities.

(II) Operation Management

The company identifies integrity factors throughout the management process, establishes an evaluation table, and develops control measures.

Table 5 Integrity Factor Analysis and Control Measures Table

| Serial Number |

Process Name |

Factor Category |

Integrity Factor Score Analysis |

Breach of Trust Performance |

Consequences of Breach of Trust |

Control Measures |

Breach of Trust Risk Assessment Analysis |

Is it a major breach of trust factor? |

|

| Possible Nature |

General Nature |

||||||||

| 1 |

Design and Development Planning (Project Review, Project Plan Preparation, Design and Development Input) |

Personnel Structure |

Employees need to keep confidential |

Leakage of formulas, etc. core confidential information |

Company confidential information leakage |

Employees sign confidentiality agreement |

Very few |

General |

No |

| Employees need to Need to be honest and trustworthy |

Conceal personal and work situation |

Employee integrity Insufficient |

Employees Sign an agreement |

Very few |

General |

No |

|||

| Whether it has market research capabilities |

Distorted research information |

Design planning is not correct |

Training |

Very few |

General |

No |

|||

| Confirmed project The person in charge's business quality is not strong |

R&D is not going smoothly Favorable |

Project progress slow, poor quality |

Training, examination Verification |

Very few |

General |

No |

|||

| Environmental facilities |

Whether it has various professional equipment |

It is unclear whether it has various professional equipment (at the beginning of the project, the company may decide to use equipment that is not very suitable for the project test) |

Product R&D cannot be carried out smoothly |

Establish equipment management archives |

Very few |

General |

No |

||

| The company lacks integrity atmosphere |

Work situation reflection Not true |

Employee integrity Poor |

Build integrity Corporate culture |

Very few |

General |

No |

|||

| System implementation |

Whether to timely absorb relevant standards issued by the state Collection |

Failure to understand and utilize the newly distributed national standards |

Use of illegal raw materials, or the amount added does not meet the requirements; the product is not qualified |

Timely acquisition and update of relevant laws, regulations, and national standards |

Impossible |

Serious |

No |

||

| Whether the selected raw materials meet national regulations and standards standards |

Does not meet national regulations and standards |

Use of illegal materials |

Timely acquisition and update of relevant laws, regulations, and national standards |

Impossible |

Serious |

No |

|||

| Product development Relevant regulations |

Failure to follow regulations Work |

The project cannot be completed on time with guaranteed quality Completed |

Training, examination Verification |

Very few |

General |

No |

|||

1. Product design integrity management

The company's product design and R&D strictly follow the "Design and Development Control Procedure", from R&D project establishment, various activity records during the process, R&D process summary, to management evaluation, controlling the entire process related to R&D.

2. Raw material or component procurement integrity management

The company classifies materials into three categories (A, B, and C) based on the risk level of the materials to product quality. For Category A material suppliers, in addition to meeting the legally required qualifications, regular on-site audits are also required. For Category B material suppliers, the company must first conduct a risk analysis of the material and decide whether an on-site audit is needed based on the quality of the material provided by the supplier. For Category C material suppliers, generally only the qualifications are audited. After the company conducts qualification audits and on-site audits of material suppliers, material suppliers that meet the requirements and are approved for procurement should establish quality files. All batches of purchased raw materials are subject to full inspection; any raw materials that do not meet the specified standards are not allowed to be stored or used.

Regarding equipment and component procurement, the relevant qualifications of suppliers are strictly reviewed. When procuring equipment and components, standard parts are purchased and used whenever possible; for parts requiring special processing, the effect of use must be fully verified to ensure that they meet the company's requirements. All equipment must undergo equipment verification before use to ensure that it meets product process requirements.

3. Production process integrity management

The company's production department and technology department are specifically responsible for the production management and technology management of various products. Various production management systems, work standards, job operating procedures, and various process procedures, management procedures, and standard operating procedures have been formulated and gradually improved. On-site training in the workshop and pre-shift and post-shift meetings are used to provide comprehensive job skills training for operators at various positions, requiring certification before taking up their posts. Various methods are used for supervision and assessment to enhance employees' quality awareness and improve operational skills. During the production process, managers at all levels strictly fulfill their management responsibilities, conduct timely inspections, and promptly correct errors to ensure stable production order.

Before adding materials, the raw materials, auxiliary materials, and packaging materials required for production are reviewed to ensure the quality of intermediate products and finished products. The "three no" principle of "no production, no acceptance, no transfer" for non-conforming products is strictly implemented. Quality control points are set for key processes to urge employees to conduct self-inspection and mutual inspection, implement monitoring and verification procedures, and strictly manage batch number records, ensuring that receipt, issuance, and verification are unified. Material balance is performed for each production step to ensure that the input of materials and the output of products are consistent with the planned requirements, confirming that there are no potential quality hazards.

Production records are reviewed, printed, and kept by the production department. Employees must fill out production records promptly as required, ensuring that the handwriting is clear, the content is true, the data is complete, and the operator and reviewer sign for confirmation. After each batch of production is completed, the workshop statistician summarizes and reviews the records, promptly submits them to the production department, and after review and confirmation, organizes and files them by batch number, managed by a designated person.

19

Based on industry characteristics and actual conditions, the company strengthens the level of information construction in the production process, uses the production management module of the ERP system to collect and monitor the entire process, implements systematic management of the company's entire production process, taps internal potential, leverages the strength of technical backbone personnel, conducts continuous improvement or technological innovation work on existing equipment, establishes a technical task force to tackle weak links; production employees must undergo training and assessment before taking up their posts, establish personnel training files, and conduct training through various methods such as centralized training, pre-shift meetings, "passing on, helping, and guiding," and visualization to strengthen their work skills and quality awareness. Production employees strictly abide by workshop discipline.

The company implements a refined production organization model to shorten the production and delivery cycle, quickly adapt to the fluctuations in the variety and quantity of market orders, meet customer needs while reducing inventory, meet customers' comprehensive understanding of the performance of pneumatic braking systems and further recognition of product quality, increase order rates, and largely solve after-sales quality problems, reduce the workload of after-sales service personnel, and make after-sales service arrangements more flexible.

(5) Marketing Management

According to strategic requirements, the company segments the market to improve the effectiveness and targeting of resources and operations. The company divides customers into direct customers and indirect customers. It determines the needs and expectations of different types of customers, determines appropriate methods based on their needs and expectations, establishes corresponding systems and teams, establishes various channels and methods, and specifically understands customer needs and expectations.

Table 6 Identifying Customer Needs and Expectations to Implement Differentiated Marketing Strategies

| Importance |

Characteristics/Needs |

| Strategic Customers |

Form strategic partnerships, key customers to develop and maintain, large purchase volume and amount, stable purchase frequency, High product quality requirements |

| Important Customers |

Relatively important customers, larger purchase volume and amount, stable procurement, high requirements for quality and timely delivery |

| General Customers |

Small purchase volume and amount, unstable frequency, price-sensitive, low loyalty |

The company uses channels such as exhibitions, industry conferences, industry standard committees, public media, the Internet, and external organizations, and methods such as questionnaires, face-to-face or telephone interviews, observation inquiries, and external commissioning to understand customer needs and expectations.

Various departments of the company regularly collect customer information, analyze it, and classify and summarize the determined customer needs information according to different market segments to form a database of needs and expectations for different customer groups. Summary materials on the overall needs characteristics of different segmented market customer groups are derived from this and used for reference in decision-making for product planning, product development and design, and process control.

The company upholds a service tenet of "Professionalism, Passion, Thoughtfulness, and Timeliness." Through publicity and training, all levels of personnel understand and consistently implement this service tenet.

20

The company advocates a corporate spirit of "Challenging the Future, Pursuing Excellence," relying on technological development and striving for growth through optimal service. Our tenet for technical support and service is "Professionalism, Passion, Thoughtfulness, and Timeliness." Our service principles are "Customer First, Service First, High-Quality Service, and Timely Response." The quality and efficiency of our service

Timeliness is crucial to the company's positive image in the eyes of customers and its future development. Therefore, we aim to provide customers with superior products and services, thereby enhancing customer recognition and improving the company's reputation and brand awareness.

The company implements a service management system based on the "Commodity After-Sales Service Evaluation System" GB/T 27922-2011, establishing a "Service System Manual," "Service Procedure Documents," and "Service Management Documents." This encompasses standardized management of service from basic after-sales service work standards, after-sales service management systems, requirements for personnel interacting with customers, after-sales service performance appraisal systems, to user complaint classification and detailed indicators, and service provision standards.

22

V. Quality Management Foundation

(1) Standard Management

The company integrates enterprise standardization throughout the entire production process. Relevant standards are established for every link, from the procurement of raw and auxiliary materials and packaging materials to the inspection of semi-finished and finished products. This ensures that the entire production process, from the entry of raw and auxiliary materials to the shipment of finished products, is under standardized and regulated management, laying a solid foundation for stabilizing product quality and improving enterprise management levels.

Figure 3 Quality Management System Document Planning Table (See Management Manual)

Figure 4 Order Acceptance and Review Process (Product and Service Requirements) (See Management Manual)

Figure 5 Supplier Management and Procurement Management Process (External Provision Process, Product and Service Control) (See Management Manual)

- Metrology Management

The company strictly implements documents and regulations such as the "Measurement Law of the People's Republic of China." A complete set of management documents and control methods has been established for various stages, including raw material procurement, process management, production equipment, inspection equipment, process inspection, and finished product inspection. Dedicated and part-time metrology personnel are responsible for the management, allocation, and regular calibration of the company's in-use measuring equipment. Emphasis is placed on professional training for metrology management personnel, providing strong support for the standardization of the company's metrology management.

To ensure product quality, strict process control is implemented in the product production process, and metrology management is strengthened for raw and auxiliary materials, etc., in the production process to ensure the normal operation and accuracy of measuring equipment.

The company strictly follows the approval plan and management procedures for the procurement, warehousing, and delivery of measuring instruments. The warehouse has dedicated personnel to manage measuring instruments, establishing account books and registration procedures. The use of measuring instruments must pass verification, and only those with a valid verification certificate can be put into use; in-use measuring instruments are strictly calibrated according to the cycle, strengthening on-site inspections and supervision, understanding their usage, and addressing problems promptly; corrective opinions are provided to departments with problems, and active and effective measures are taken for rectification, laying a solid metrological foundation for the production of high-quality products.

(3) Certification Management

The company has currently passed ISO9001 quality certification and various product certifications, and is preparing for "Made in Zhejiang" brand certification. The company will strictly follow the international quality management system to ensure the quality of its products, thereby ensuring that the company's quality policy of "Customer is our top priority, meticulous work, compliance with regulations, continuous improvement, energy saving and emission reduction, pollution reduction and efficiency improvement, health protection

23

Safety first, environmental protection, risk avoidance" can be successfully implemented. Since its establishment, the company has never experienced

major quality complaints, and the pass rate has reached 100% in annual inspections by various levels of quality and technology departments.

(4) Inspection and Testing Management

The company has purchased a large number of advanced equipment for testing, including energy dispersive X-ray fluorescence spectrometer, spectrometer ROHS software, spectrometer thickness analysis software, and microcomputer-controlled electronic universal testing machine.

The company conducts inspection and testing of incoming goods to ensure that the materials provided by suppliers meet the specified requirements. The quality department is responsible for compiling incoming inspection and testing procedures and for random inspections of incoming materials; the procurement department is responsible for non-conforming materials, and the material warehouse is responsible for checking the quantity, name, and weight of incoming materials.

To ensure that all products pass the specified inspection before entering the next process, the company has formulated "Nonconforming Product Control Procedures," "Shipment Inspection Control Procedures," and "Final Inspection Control Procedures" to conduct strict process inspections and tests. The quality department is responsible for formulating process and final inspection and testing procedures, establishing final inspection points, and organizing process inspection work; quality inspectors are responsible for checking inspection points, semi-finished products, and finished products; and production workers in each workshop are responsible for self-inspection.

Table 7 Testing Equipment Used by the Company

| Serial Number |

Equipment Name |

Unit |

Actual Quantity |

| 1 |

Zoller Tool Testing Instrument |

Unit |

1 |

| 2 |

Klingelnberg Measuring Center |

Unit |

2 |

| 3 |

Gear Radial Runout Tester |

Unit |

2 |

| 4 |

Hardness Tester |

Unit |

1 |

| 5 |

WANGONG Display |

Unit |

1 |

| 6 |

Pneumatic and Electric Electronic Column |

Unit |

1 |

24

VI. Product Quality Responsibility

(1) Product Quality Level

1. Quality Level

The company continues to expand its "refined, specialized, and innovative" R&D team, continuously improving product technology levels and quality performance. In recent years, products have repeatedly received recognition from customers and peers,

Table 8-1 Performance Results Related to Quality Management Level

| Service Performance Indicators |

2022 |

2023 |

2024 |

| First-time Inspection Pass Rate (%) |

94.65 |

95.87 |

96.34 |

| Return Rate (%) |

2.6 |

2.4 |

2.2 |

| Customer Customization Achievement Rate (%) |

100.0 |

100.0 |

100.0 |

| Contract Fulfillment Rate (%) |

100.0 |

100.0 |

100.0 |

| Customer Complaint Handling Rate (%) |

100.0 |

100.0 |

100.0 |

| Customer Complaint Handling Satisfaction (%) |

95.5 |

96.0 |

98.0 |

2. Product and Service Innovation

Regarding the current state of the gear hobbing cutter market, the demand for gear hobbing cutters of different grades in the domestic market is constantly increasing. Foreign famous brands are penetrating the domestic high-end product market, intensifying competition across the industry, and strengthening brand awareness.

In 2023, the brand upgraded and proposed a new concept of "活力上优.保持热爱" (Vitality Shangyou. Maintain Passion). Shangyou encourages every urbanite to travel and exercise more, live vibrantly, and maintain a positive attitude towards life's beautiful things, striving to allow users to enjoy and experience a wonderful day through healthy and innovative Shangyou products.

Table 13 Company Patents (Partial)

| Serial Number |

Patent Name |

Patent Number |

| 1 |

A kind of rectangular spline alloy hobbing cutter |

ZL 2022 2 2223097.5 |

| 2 |

A kind of worm hobbing cutter |

ZL 2022 2 2157492.8 |

| 3 |

A kind of asymmetrical pressure angle worm wheel hobbing cutter |

ZL 2022 2 1096173.4 |

| 4 |

A kind of new broaching cutter |

ZL 2021 2 0868539.4 |

| 5 |

An invention patent for a worm wheel hobbing cutter that prevents damage from chip adhesion |

ZL 2020 1 1380532.4 |

| 6 |

A kind of pre-grinding broaching cutter |

ZL 2022 2 2196733.X |

| 7 |

A machine tool for processing the return stroke groove of a shaving cutter |

ZL 2017 1 1174434.3 |

| 8 |

A kind of direct-spray quick-cooling broaching cutter assembly |

ZL 2022 2 2521453.1 |

| 9 |

A kind of hobbing cutter that eliminates tool wear and machining accuracy by adjusting the cutter head |

ZL 2021 1 0536927.7 |

| 10 |

A kind of helical full-cut broaching cutter |

ZL 2023 2 0959621.7 |

| 11 |

A kind of high-precision cutting blade |

ZL 2023 2 0983679.5 |

| 12 |

A kind of gear hobbing milling cutter blade |

ZL 2023 2 2351657.X |

| 13 |

A kind of rod-type double hobbing cutter |

ZL 2023 2 2262893.4 |

| 14 |

A kind of large helix angle worm hobbing cutter |

ZL 2023 2 2241265.8 |

| 15 |

A kind of new type of insert gear hobbing cutter |

ZL 2023 2 2624803.1 |

| 16 |

A kind of full-cut hobbing cutter |

ZL 2023 2 1853691.0 |

| 17 |

A kind of hobbing cutter for gear processing |

ZL 2024 2 1766897.4 |

| 18 |

A kind of special-shaped insert blade |

ZL 2024 2 1766646.6 |

(II) Product After-Sales Responsibility

1. Strengthen customer relationship management through multiple channels

The company strengthens customer relationship management through multiple channels and strengthens after-sales management:

(1) By establishing extensive customer relationships, providing feedback channels in multiple ways and comprehensively, quickly processing customer information, and continuously improving service quality. Maintaining customer relationships is not just the work of the after-sales service department, but a process involving all staff. The company adheres to the service philosophy of "feedback in the first instance" to provide services, ensuring customer satisfaction through comprehensive services across various channels.

(2) Once a customer establishes a cooperative intention with the company, the company will maintain communication with the customer from aspects such as product research and development, implementation, monitoring, and service, establishing a comprehensive cooperative relationship. All resources can be mobilized to provide services to customers. In recent years, the company has been committed to transforming from a traditional manufacturing enterprise into an enterprise providing comprehensive services, being market and customer-oriented, and continuously meeting customer needs.

(3) The sales department promptly feeds back relevant information to customers based on customer orders, and makes timely adjustments to meet customer needs if there are any changes during the process.

(4) The company establishes information transmission channels for customers, mainly including the following:

Professional customer service personnel collect information through telephone, fax, email, QQ, and WeChat;

Entrusting third-party surveys to provide feedback;

Establishing a WeChat public platform to transmit information;

Various inquiry and feedback information channels to obtain opinions, suggestions, and complaints.